Within the overlapping spheres of Total Quality Management and Lean Manufacturing, one Japanese word continues…

Spotlights on for Quality Guru, Dr. Joseph M. Juran

Dr. Joseph Moses Juran (1904-2008) is regarded as the Father of Modern-Day Quality Management, thanks to his many contributions in the field of quality. His teachings and quality philosophies helped Japan into becoming a market juggernaut, and he influenced the Western manufacturing industry through his teachings on quality management. He had over 70 years of active work in the quality field and played a number of other roles – engineer, teacher, trainer, consultant, and writer.

In 1951, Juran published the Quality Control Handbook, the classic go-to guide of quality practitioners. Before and after that, he also authored notable books and references such as Quality Planning and Analysis (1971), Statistical Methods Applied to Manufacturing Problems (1926), and Managerial Breakthrough (1964).

In 1979, Juran founded his own training and certification company, Juran Institute, based in Southbury, Connecticut. It provides training and consultancy services in quality management, business process improvement, Lean manufacturing, etc. The establishment of the Juran Institute amplified the reach of Juran’s teachings and influence in a global scale. It is known as one of today’s leading quality management consulting agencies in the world.

The Juran Trilogy and Quality Planning Road Map

Though Juran’s message on quality was fairly universal and resounded throughout many industries, he focused on the broader issues like planning, management’s role in enforcing quality, and the significance of setting targets for improvement. He was quoted as saying, “It is most important that top management be quality-minded. In the absence of sincere manifestation of interest at the top, little will happen below.”

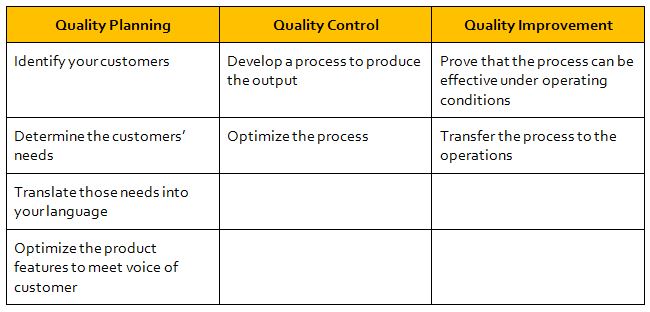

He believed that managing for quality is no walk in the park and that quality is never attained either merely by luck or accident. He summarized the quality management process in a “trilogy” concept – Quality Planning, Quality Control, and Quality Improvement.

Each element has a series of actions with corresponding outputs, and in each action, measurement of performance is required.

- Quality Planning – developing product, services, or features that meet customer needs.

- Quality Control – putting in place processes that ensure products and services meet the standards

- Quality Improvement – raising the level of quality in a continual manner.

Pareto Principle

While the Pareto Principle is not entirely credited to him, Juran was known for popularizing the term and its usage in the quality field in 1937. As was originally intended by the Italian economist, Vilfredo Pareto, the principle was initially introduced to serve as a mathematical model that explains the unequal distribution of wealth. Juran further developed Pareto’s idea to describe any situation where a small percentage of causes is responsible for the large percentage of effect.

The idea of ‘the vital few and the trivial many’ resonated with Juran in his years as a young engineer. Time and again, he noticed that when defects are listed based on their frequency of occurrence, a relatively few types of defects accounted for the bulk of defects found.

With the help of another economist, MO Lorenz, in publishing the first edition of the Quality Control Handbook, Juran was in dire need of a shorthand description of Pareto’s idea. He thus promoted the colloquial term for the Pareto Principle, which is the 80:20 rule, meaning 80% of the results is brought about by 20% of the overall effort.